The LCEP curriculum is available in two forms; virtual and in-person. The program culminates in an exam to earn the CM-Lean credential. Learn more.

Only approved instructors teach the LCEP course, otherwise units aren't honored for the CM-Lean credential. Learn more.

Chapters, Organizations, and Educational entities facilitating the curriculum in-house have a variety of resources. Learn more.

Lean FAQ's, FREE beginner video series, Lean Construction Forum info, and other additional resources. Learn more.

Lean Construction Education Program

Everyone related to the construction process has an incentive to get the project done faster and at a lower cost - from the project owners who want to see results for their investment to the contractors and designers who want to do their job well and move on to the next project.

With AGC's LCEP Program, Construction professionals at all experience levels learn the building blocks necessary to transform their projects and companies into a Lean Operating System.

Lean Construction Education Program

Everyone related to the construction process has an incentive to get the project done faster and at a lower cost - from the project owners who want to see results for their investment to the contractors and designers who want to do their job well and move on to the next project.

With AGC's LCEP Program, Construction professionals at all experience levels learn the building blocks necessary to transform their projects and companies into a Lean Operating System.

Students of the Lean Construction Education Program can choose from two formats of instruction; virtually or in-person. Where you begin also depends on your level of knowledge and experience with Lean principals. Those who are just beginning their Lean journey can start with the free Lean 101 course, while others will be ready to choose an upcoming course to attend.

Virtual courses are facilitated live via our AGC EDGE program.

In-person training is provided by our various Chapters.

Below is a quick breakdown on how students can get started with more detailed descriptions under the tabs.

- FREE Lean 101 introductory course is available for beginners or those who need a refresher.

- Depending on your availability and location, you'll select whether In-Person or Virtual instruction is best.

- Complete the five units in LCEP and apply for your CM-Lean exam.

- Passing scores of 105 or higher receive their CM-Lean credential.

- Once earned, the CM-Lean credential does not expire.

The purpose of this program is to develop the participant’s level of awareness and understanding of Lean and Lean Construction practices and prepare them to take the CM-Lean credential exam. The focus will be to reach understanding for construction phase practices and awareness for the other phases of project delivery.

Participants will develop a foundation in Lean principles to start learning by doing Lean Construction practices relevant to the construction phase of a project. Some of these practices include: the Last Planner System, the PDCA cycle, problem solving, waste removal, 5S, facilitation, planning for flow efficiency, and engaging people.

AGC’s Lean Construction Education Program (LCEP) course is comprised of five units that function as the building blocks of a wholistic approach to educating aspiring Lean Construction practitioners. This program provides 36-hours of instruction and training to provide construction industry professionals at all levels with the knowledge and skills to take advantage of the benefits of Lean Construction. Click on the course objectives below to learn more about each unit.

Unit 1 is an introduction to Lean Construction and its guiding tenets.

- Lesson 1 – Why Lean?

- Lesson 2 – What is Lean & Respect for People

The first two lessons answer the questions Why Lean? and What is Lean? Then it introduces participants to the six tenets of Lean Construction and explains how Respect for People is a fundamental goal of Lean as we work to develop people and make work an enriching experience. - Lesson 3 – Generate Value, Remove Waste, & Optimize the Whole

Explains the way value is defined by the customer, and that each customer will define value differently. Instructors illustrate that non-value-adding activities are pure waste. Lean uses the principle of prioritizing flow efficiency as a key means to generate value and remove waste. - Lesson 4 – Continuous Improvement

Defines continuous improvement and provides an understanding of how Plan-Do-Check-Act, PDCA, supports continuous improvement. Participants will practice PDCA in a group exercise.

Unit 2 introduces Lean Construction processes and how they work, diving deep into the last tenet, Focus on Process and Flow.

- Lesson 1 – Process, Efficiency & Variation

Provides a description of what a process and process flow are, then describes what makes a process efficient. From there instructors define what variation, what it looks like in our work, and what causes it, so in the next lesson we can see how variation impacts a process, its flow, and its efficiency and what that means for our projects. - Lesson 2 – Law of Variation

Explains how variation, buffers, and consistency affect project performance, and identify the characteristics and consequences of unreliable workflow and reliable workflow. Participants will learn these lessons firsthand in the Parade of Trades simulation. - Lesson 3 – Variation Mitigation

Describes buffers, buffer sizing and other means to mitigate variation. Participants learn specific techniques for reducing variation, and the importance of process consistency. - Lesson 4 – 5S

Shows how 5S is another Lean method to help reduce variation on projects, and it does much more. It is a means for pursuing continuous improvement. It helps us reduce waste. It shows respect for people by improving their work environment and contributing to a safer workplace.

Unit 3 is a continuation of the discussion of Lean production systems which falls under focus on flow that along with the other tenets of Lean form the basis for the Last Planner System and other Lean Construction Methods.

- Lesson 1 – Lean Production Systems

The overall lesson objective is to introduce key terms and recognize aspects of common practice to create a Lean production system for construction that prioritizes flow efficiency. - Lesson 2 – Batch-Pull-Balance-Takt Simulation

Participants experience the effects of batching, pull, balancing and takt on a production system by completing the Batch, Pull, Balance, Takt Exercise. - Lesson 3 – Lean Production Systems – Pull

The focus is on Pull as part of the control for the system. Participants learn how pull helps manage variation and explain the impact of pull control on production systems. - Lesson 4 – Lean Production Systems – Law of Bottlenecks & Balance, Little’s Law & Batching

The overall objective for this lesson is for participants to recognize the impact of batching on construction production and flow efficiency by looking at Little’s Law and the risks and advantages of batching.

In Unit 4 we examine the Last Planner System®, LPS, for the construction phase of project delivery and how it applies the six tenets of Lean Construction.

- Lesson 1 – Introduction to Last Planner System® (LPS)

Describes how the LPS is a method of planning and control for the entire project. LPS is a common starting point for companies or projects embarking on a Lean journey. This lesson introduces LPS in terms of how it embodies the six tenets both in its design and goals in the context of field production. - Lesson 2 – Details of the Last Planner System

Describes the ideal for running the full LPS. Participants will learn the different tools, visuals, and formats that are used, but their goal of each conversation is the same.This lesson shows the steps of the Last Planner System and how it gets more detailed the closer teams get to the work. As the lesson progresses participants see the purpose of each level of the LPS, and how the levels of the LPS work together. Participants will identify methods to encourage trade partner participation in each level of the LPS, and measure to see if processes are being followed and achieving the desired results.

In Unit 5 we show how the six tenets are applied to the other parts of project delivery.

- Lesson 1 – Lean Project Delivery

Describes how Lean is applied to the whole project delivery system. It explains the purpose and recognizes the advantages of cross-functional teams, and why value should be defined early in the project life cycle. - Lesson 2 – Lean in the Supply Chain

Looks at improvements that can be made exclusively within the supply chain with an understanding of customer value but without involving changes by design or construction. - Lesson 3 – Lean in Design

Describes how value creation in design focuses on identifying and meeting customer needs through efficient and effective design processes. - Lesson 4 – Process Improvement & Problem Solving

Explains how effective problem solving is focused on proactively preventing the same type of problem from occurring again because it addresses root causes. It creates a culture of problem solving where everyone brings problems forward and collaboratively works to resolve them.

The Lean Construction 101 course serves as the introductory course to the AGC Lean Construction Education Program and is the starting point for your Lean Construction journey.

This 50 minute self-paced e-learning course provides a foundation of the key concepts and terms used in Lean Construction, providing you with the background necessary to further your Lean Construction education.

Following this course, you will be able to:

- List examples of Lean Construction in practice

- Discuss the benefits of Lean Construction

- Define Lean Construction

- Explain the origins of Lean Construction

- Describe Lean Construction tools

- Identify Lean Construction implementation opportunities

Click on the link below to participate in the self-paced interactive course.

In-seat LCEP courses that are offered within the United States are facilitated in two ways.

- AGC Chapters facilitating the curriculum locally

- Member companies offering LCEP internally to staff

All curriculum, whether offered at an AGC Chapter or by a Member company, must be facilitated by AGC approved instructors who've met necessary instructor requirements and have been evaluated by AGC appointed Subject Matter Experts.

To find upcoming in-person training:

- Visit the course calendar to view upcoming in-seat LCEP offerings

- Find a local chapter or contact your Chapter to request they facilitate the LCEP curriculum in the future

- Not a member? You're not required to be a member to take an LCEP course. Complete the membership form for additional information.

International In-Seat Instruction

AGC has partnered with LCI-Qatar to offer the Lean EP and CM-Lean credential. Please reach out to {https://lci.qa/} for more information.

AGC EDGE offers live, virtual, instructor-led courses that are written for contractors, by contractors, and taught by contractors. Whether you're a general contractor or specialty contractor focusing on horizontal or vertical projects, the EDGE virtual courses speak to your business and help set the level of consistency practices across your organization. It's the same high-quality learning experience and expert instruction you expect from AGC in-person classroom training from the comfort of your home or work computer.

Most of our courses start monthly and those offerings vary in length of class session, time of day and day(s) of the week they are presented, so there is something available for everyone's schedule and time zone.

Why AGC EDGE live virtual courses?

- These are live-taught virtual courses - meaning all students and the instructor ae online at the same time.

- The courses are not one way, log in and tune out webinars; they are facilitated discussions based on a core curriculum, with activities and breakout rooms.

- Webcams and microphones are required, and students are expected to participate openly and actively.

- Interact with people from other organizations from around the US and sometimes the world.

- Leverage the experience and knowledge of the instructor and fellow students.

- Flexible course schedule - pick the course that best works with your schedule.

The AGC Certificate of Management-Lean Construction (CM-Lean) is an assessment-based certificate credential that denotes knowledge and understanding of concepts related to lean adoption, practice and process transformation outlined in AGC’s Lean Construction Education Program. Successful candidates will carry the CM-Lean designation.

To prepare for the CM-Lean exam:

- Successfully complete all five LCEP courses and provide AGC with a record of completion prior to exam application.

- Apply for the CM-Lean exam which are posted on the 15th and last day of each month. Test takers have three months to complete the exam after application approval.

- All fees total $575 and will be collected at one time after the candidate application is reviewed and approved.

The CM-Lean Exam Prep Course is an optional three hour self-paced e-learning course reviews the principles of Lean Construction as taught in AGC's Lean Construction Education Program. The course is designed to supplement learner's review and study of the curriculum's five units as they prepare for the CM-Lean exam. Course participants can assess their understanding of Lean Construction as they experience the audio and visual content and answer the 55 review questions as they progress through the five units of the CM-Lean Exam Prep Course. The cost of this prep course is $79 for members and $99 for nonmembers.

A list of CM-Lean Holders are retained and can be found below. Have your CM-Lean and not listed? Let us know at cm-lean@agc.org so we can share your accomplishment.

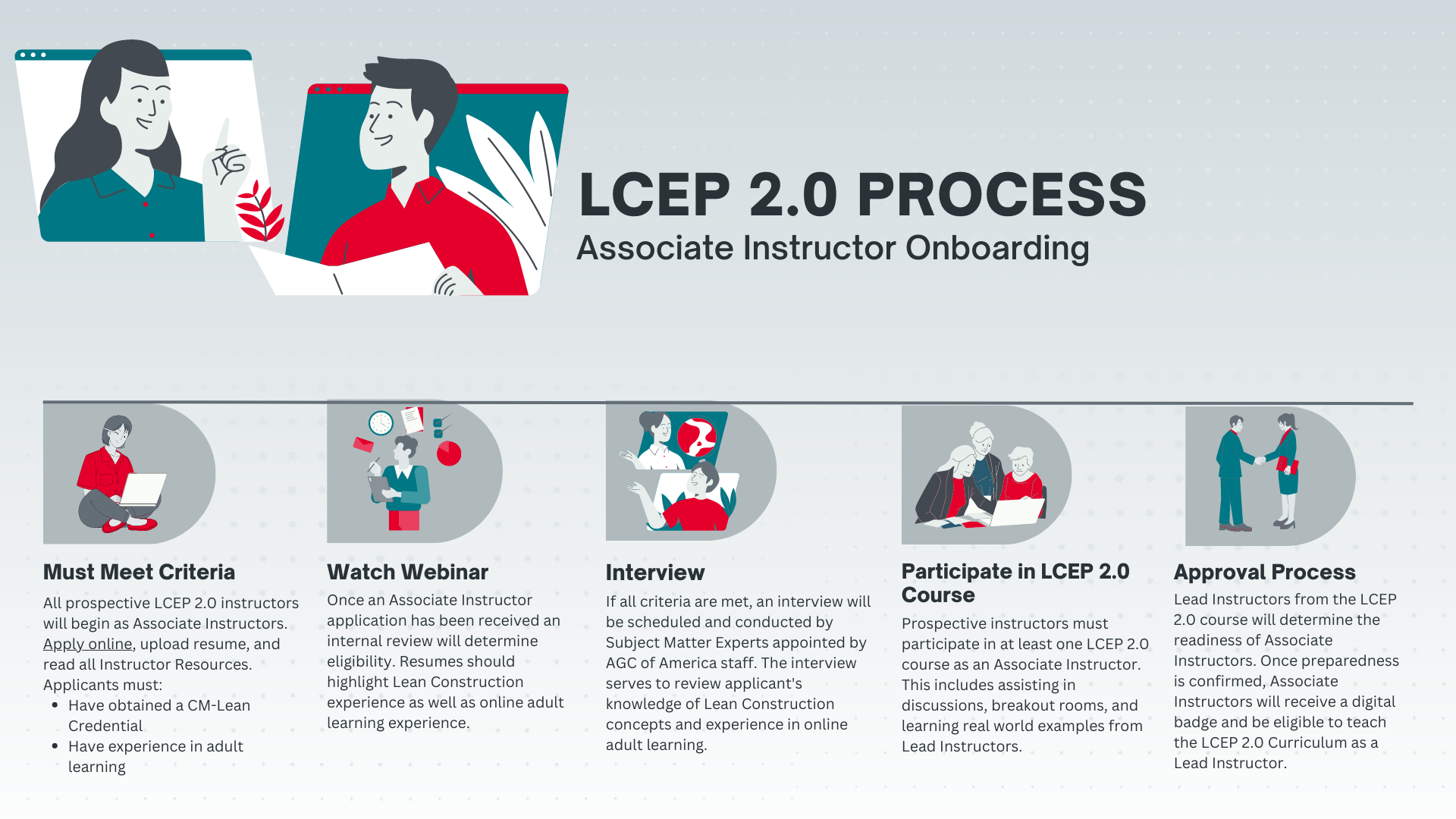

What are the Requirements for LCEP Instructors?

- Hold a current CM-Lean credential.

- Submit an application and resume. Previous LCEP Instructors must re-apply.

- Interview with SME Committee on background and teaching experience.

- Participate in an LCEP 2.0 course as an Associate Instructor.

- An infographic with more information can be found below.

Applications are reviewed by Subject Matter Experts appointed by AGC. Approved applicants will be contacted by phone or email to schedule an interview. During the interview, applicants can expect:

- SMEs will discuss applicant’s experience level in Lean construction.

- Review of the applicant's resume and/or curriculum vitae.

- Experience teaching adult learners, their background and qualifications.

Based on the interview, newly appointed Associate Instructors will receive a digital badge that indicates the combination of the CM-Lean credential and Associate Instructor designation.

A few of the benefits of being an LCEP instructor include negotiating honorariums with chapters and organizations, having opportunities to travel, engaging in the Lean community, and so much more.

Lead Instructors and Associate Instructors need to read the LCEP Guidelines for Associate Instructors. Under the Associate Instructors tab, a checklist is available for Lead and Associate Instructors to use to ensure the expectations are understood.

Participating in an LCEP 2.0 course

All newly approved instructors must participate in an LCEP 2.0 course as an Associate Instructor. The Lead Instructor of the course will have Q&A check-ins every class day with Associate Instructors. The full list of LCEP Associate Instructor Guidelines should be reviewed. Associates are expected to:

- Facilitate discussions

- Help in breakout rooms

- Learn simulations and games

To ensure the expectations of Associate Instructors are understood, the Associate Instructor Checklist should be used by Associate and Lead Instructors. At the close of the course, Lead Instructors of the courses will complete an Associate Instructor appraisal form to determine readiness for the next step. Lastly, after the form is reviewed by AGC, Associate Instructors will become Lead Instructors. Organizations should provide the Instructor Guide to Associate Instructors before the course they participate in. Associate Instructors are not required to purchase Participant Manuals, but the AGC Marketplace is where materials are found.

Requirements of Lead Instructors

While Associate Instructors have the option to purchase materials, Lead Instructors of LCEP 2.0 are required to purchase the Participant Manuals before the start of the course they will be instructing. These materials are be available on the AGC Marketplace.

Lead Instructors also have access to AGC’s Learning Management System to review PowerPoint slides and additional resources. The Lead Instructor designation is awarded for three years. Those who wish to remain Lean Instructors will need to instruct at least two LCEP courses within that time, submit a renewal application, and upload an updated resume, otherwise the Lean Instructor designation will expire.

Guidelines for Lead Instructors should be reviewed to understand the expectations of Lead Instructors as mentors. When Lead Instructors host Associate Instructors in their course, an Associate Instructor appraisal form should be completed.

Wrapping up the Course

Course instructors and/or administrators are required to document attendance utilizing the classroom roster template provided below. Students must attend at least 90% of each unit to receive credit for completion of a course.

Following the completion of classroom instruction, course instructors and/or administrators must upload the completed Roster Template provided to the Upload Course Roster button below.

Rosters that are not submitted online will not be entered into the AGC Nationwide Curriculum Database and will not count towards required units taken to apply for the CM-Lean credential.

Each student who successfully finishes training should be recognized with a certificate of completion. Chapters can download the Certificate of Completion on the Chapter Exchange page and instructors can find it in the LCEP 2.0 Approved Instructor course.

AGC's Lean Construction Education Program is designed for local delivery. The three options to facilitate the in-seat trainings are:

- Local AGC Chapter trainings

- Organizations, construction firms, internal trainings

- Local community colleges or joint-apprenticeship training program

Chapters hosting in-seat courses should use the Chapter Exchange for info and can add course offerings to the AGC Course Calendar.

AGC of America, along with industry experts, develops instructor and participant resources for the delivery of this training to ensure the same quality program no matter where courses are offered across the country.

The AGC Chapter map provides contact information for all the US Chapters. International organizations and associations in Qatar and Canada also facilitate courses. For more information, contact education@agc.org.

AGC’s Lean Construction Education Program may already be available at an AGC Chapter near you. View a listing of currently scheduled courses or Click Here to contact your local AGC Chapter to learn more. To prepare to host an LCEP course:

- View the course descriptions to learn more about what is in each Lean Construction Education Program unit.

- Approved Instructors: Potential instructors must become approved by AGC of America to deliver this training. Courses facilitated without an approved instructor will not be entered in the national database and will not count toward the requirements for the credential. The LCEP instructor approval process and the requirements can be found in the Instructor section.

- AGCA maintains an approved instructors list that can be obtained by emailing curriculum@agc.org to aid in locating an instructor.

- If your organization has a Lean Champion with a CM-Lean credential, have them review the Instructor Resources section to become an approved instructor.

- Participation: We suggest that you have at least 10-15 individuals that you wish to take each course (or the entire five unit program) to encourage maximum participation. Have less than five registered? Consider sending them to the EDGE program for virtual-live instruction.

- Purchase Materials: AGC Member pricing is available on all manuals so be sure to login to the AGC Marketplace to find pricing. Organizations offering the course are required to provide One Participant Manual per student and an Instructor Guide if the facilitator requires one.

- Required Documents: AGC provides certificate templates and roster templates as well as other resources you need on the course date in the Instructor Resources section.

- Following the course be sure to direct your participants to the online evaluation found at lean-evaluations.

- Submit Rosters: Course administrators or instructors should upload the rosters to the Curriculum Upload Portal. This roster and Evaluation online survey will be used to verify contact and completion information.

Questions can be directed to curriculum@agc.org.

Outside groups are able to host the Lean Construction Education Program (LCEP) either internally with an approved instructor, or they can partner with one of their local AGC Chapters.

The Instructor's Guides provide a detailed look at the contents of each course, providing the instructor with lesson plans, PowerPoint presentations, discussion guides and answers to worksheets and case studies. The Participant’s Manual accompanies the Instructor’s Guide and is sold separately for each participant and provides the instructor with the narrative course material that participants will reference throughout the class. These resources are designed to work in tandem and both are necessary to fully review the course content.

To offer the LCEP course:

- Purchase course manuals which can be purchased through the AGC Marketplace. View the course overview to learn more about what is in each unit.

- Approved Instructors: Potential instructors must become approved by AGC of America to deliver this training. Courses facilitated without an approved instructor will not be entered in the national database and will not count toward the requirements for the credential. The LCEP instructor approval process and the requirements can be found in the Instructor section.

- AGCA maintains an approved instructors list that can be obtained by emailing curriculum@agc.org to aid in locating an instructor.

- If your organization has a Lean Champion with a CM-Lean credential, have them review the Instructor Resources section to become an approved instructor.

- Templates AGC provides certificate templates and roster templates as well as other resources you need on the course date in the Instructor Resources section.

- Closing Duties Following the course upload your roster to the Curriculum Upload Portal and have participants complete the online evaluation.

Questions can be directed to curriculum@agc.org.

AGC’s Lean Construction Forum is focused on growing the implementation of lean practices in the construction industry by providing educational opportunities and developing a community where anyone with an interest in lean construction can come together to engage in a dialog on best practices, share information, and participate in a broad, coordinated effort to promote and define the use of lean concepts and processes within the construction industry. Join the Lean Forum!

Tell me a little about the AGC’s LCEP. How do I register for the courses? Are there any prerequisites to be completed before taking the courses?

Everyone related to the construction process has incentive to get the project done faster and at a lower cost - from the project owners who want to see tangible results for their investment to the contractors and designers who want to do their job well and move on to the next project. Lean Construction is based on the holistic pursuit of continuous improvements aimed at minimizing costs and maximizing value on a construction project: planning, design, construction, activation, operations, maintenance, salvaging, and recycling.

To help contractors develop the knowledge needed to build lean, AGC developed the Lean Construction Education Program. Construction professionals at all experience levels will learn the building blocks necessary to transform their projects and companies into a lean operating system.

- Unit 1 | Introduction to Lean Construction

- Unit 2 | Process and Production Basics

- Unit 3 | Production Systems

- Unit 4 | Lean Thinking Applied to Field Production, Last Planner System

- Unit 5 | Lean Thinking Outside of the Field Production

We primarily rely on AGC chapters to offer the curriculum programs throughout the country with both in-person and virtual offerings. The courses available are posted by our chapters directly on the course calendar. If you don’t see something near you, we recommend you contact your local AGC chapter to express interest and see if/when they plan on offering the courses.

Courses can be delivered virtually or in-house at construction firms. See the course calendar of upcoming courses.

Can I self-study for the course?

No. Participants must attend all five courses virtually or in a classroom environment, delivered by an approved instructor, to be eligible to sit for the exam.

Do I have to take all five courses? Can I just take the exam?

Participants must attend all five courses virtually or n a classroom environment, delivered by an approved instructor, to be eligible to sit for the exam

It is a five-course curriculum (35 hours total).

Can I take LCEP courses in multiple locations?

Yes. The LCEP is developed in a manner to allow consistent delivery across the country and you should feel free to mix-and-match training locations as your schedule allows.

Do I have to take the courses in order?

It is not required that the courses be taken in order however, the course materials do build upon each other and it is recommended that they be taken in order to maximize your experience.

Do I have to be an AGC member in order to attend the class or sit for the exam? If I want to be a member how do I join?

No, you do not need to be an AGC member to attend the course and sit for the exam. Joining AGC's membership has many benefits such as providing you with a menu of products, programs, and services to support your business. Join at a local level!

I reside outside the U.S., do I have to be a U.S. citizen or U.S. resident in order to take the courses or exam? Do you have a chapter or representative outside the U.S. to host the class and/or the exams?

No. You do not need to be a U.S. citizen or U.S. resident to take the courses or to sit for the exam.

Lean classes are now taught virtually and are open for registrants outside the US.

Currently, we also have partners who are offering the our LCEP programs in Canada and Qatar:

- Canadian Construction Association (CCA)

- Lean Construction Institute - Qatar (LCI-Qatar)

Courses can be hosted by anyone so long as the following conditions are met:

- Courses are taught by an approved instructor. See the requirements to become an approved instructor.

- Each participant has and retains their own copy of the Participant’s Manual, purchased from the AGC Marketplace, and the participant’s attendance is documented with AGC of America for each participant upon completion of each unit.

- The courses are taught as designed and to their required duration.

What is the CM-Lean credential?

The AGC Certificate of Management-Lean Construction (CM-Lean) is an assessment-based certificate credential that denotes knowledge and understanding of concepts related to lean adoption, practice and process transformation outlined in AGC’s Lean Construction Education Program. Successful candidates will carry the CM-Lean designation.

How do I earn my CM-Lean? How do I register for the CM-Lean exam? Which application(s) do I need to fill out?

Individuals earn the CM-Lean credential by:

- Completing all five LCEP courses, facilitated by an approved instructor

- Must have approved application in advance of exam administration. Once you have completed the five mandatory course and are ready to take the exam, you need to fill out the online CM-Lean application.

- Submitting the exam fee payment

- Passing the CM-Lean exam

Can I sit for the exam without taking the courses?

Participants must attend all seven courses virtually or in a classroom environment, delivered by an approved instructor, to be eligible to sit for the exam.

How much will it cost to earn my CM-Lean?

Participants will need to pay to attend all five LCEP and the exam fee. The cost of the individual LCEP courses varies by training location but is generally somewhere between $1,400 and $2,650 for all five courses. This typically includes the price for the course books.

The fee for the CM-Lean exam is $575, and in the event that you must re-take the exam there is a re-testing fee of $100.

What is covered in the CM-Lean exam?

The CM-Lean exam is based on learning concepted from within the courses. The 150 questions of the exam can be found within the course materials.

What is the format of the exam and how much time will I be given?

The CM-Lean is a 150 question, multiple-choice exam, derived directly from the LCEP course content. Each question provides four answer options with one correct option. All items on the exam will be scored with the same point value. Four hours will be given to complete the exam and total exam time is calculated in the testing software. Three months is given to complete the CM-Lean exam from the opening date of the exam exam takers are assigned to.

No. Once the CM-Lean credential is earned is does not expire.

How do I show that I’ve earned my CM-Lean?

Following passing the exam and completion of the post-exam survey participants can immediately begin using the designation “CM-Lean” following their name. Participants will also receive a certificate from AGC of America acknowledging the receipt of the credential.

What does it mean to be a LCEP approved instructor?

Instructors interested in teaching the courses must be approved by AGC of America. Following verification that the instructor meets the qualifications to facilitate that courses, they will be notified of their approval by the Director of LCEP.

Instructor approval many be revoked at any time due to poor participant evaluations or instructors failing to meet any of the standards outlined in the instructor requirements forms.

How do I become an approved instructor?

Instructors must complete the Instructor Requirements form and submit that, along with a resume detailing LCEP experience, to AGC of America. The form details the qualifications necessary to become approved to instruct the courses and other requirements, such as a review of the course materials and instructor orientation webinars.

More information on becoming an instructor can be found here.

I am an approved instructor—do I still have to attend the course as a participant to sit for the exam?

Approved instructors, who have facilitated a course in the LCEP are not required to additionally take that specific course as a participant. Instructors should submit an application and include course dates they taught each unit. All courses must be taught or attended in order to qualify to sit for the exam.

I would like to host the program at my company. How do I do this?

Courses can be hosted by anyone so long as the following conditions are met:

- Courses are taught by an approved instructor.

- Each participant has and retains their own copy of the Participant’s Manual for that unit and the participant’s attendance is documented with AGC of America for each participant upon completion of each unit.

- The courses are taught as designed and to their required duration.

For more detailed information, visit the AGC website here or email curriculum@agc.org.

AGC provides a huge amount of resources to people interested in learning more about Lean. Below are a few links to additional resources.

AGC of America Statement on IPD-ish and IPD-lite

.png)